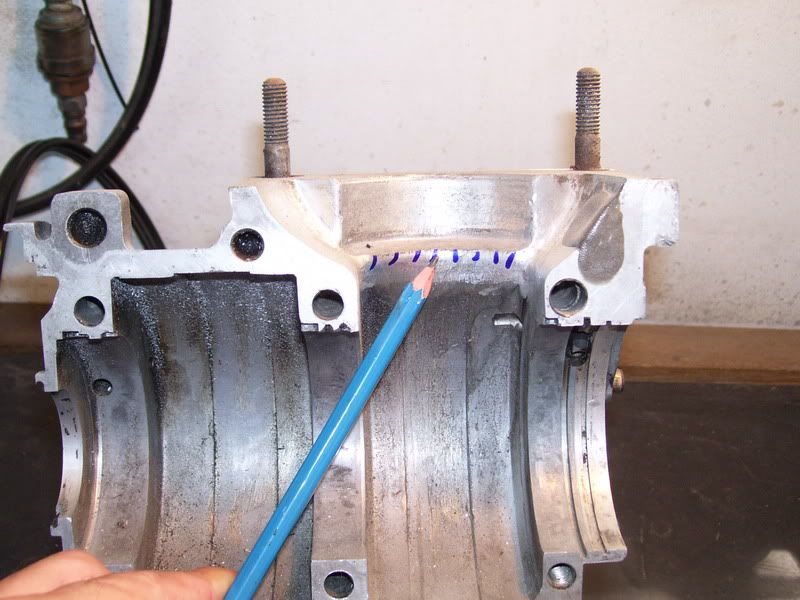

Put a lubed piston in one of your bores and sit it in its normal assembled postion on the crankcase half you are working on. Move the piston down until it catches on the crank case then simply start grinding/filing in that area until the piston slides all the way down to where bottom dead centre would be if the engine were all assembled and that's it really. Matt says chamfer all sharp edges that you make with your filing/dremeling.

For the bottom case you can still sit a barrel (with piston inside) on the two remaining studs and slide the piston down to see where it catches. You dont need to take much off to get full clearance - as you'll see yourself.

I took alot of time afterwards to banish all trace of swarf and aluminium dust from all engine surfaces.

_________________

After years of moaning about immigrants now i am one...